When your application requires you to work with series XPV titanium alloy, you might be wondering about the titanium milling cutters for this material. It is important to select the ideal carbide tip for the job, and the following guidance for selecting the right tool for the job can help you.

Select the Optimal Flute and Helix Styles

It is necessary to select the right flute and helix style when working with titanium. As a strong material, titanium requires a slightly different setup than softer metals such as aluminum. The ideal tip has four flutes. A variable helix style is best when cutting holes into titanium series XPV material.

Consider the Parameters for Cutting

You will also need to consider the parameters for cutting. Most applications require a tight tolerance for the opening. You would not want to end up with a hole that is too big or too small for the fastener or adjoining piece. The tips are available in sizes ranging from 1/8 inch to 1-inch diameters in increments of 1/16 inch. This allows you to get the right size of tip for the holes that you need to make in the sheets or formed pieces of titanium.

Keep in Mind the Ideal Applications for the Tools

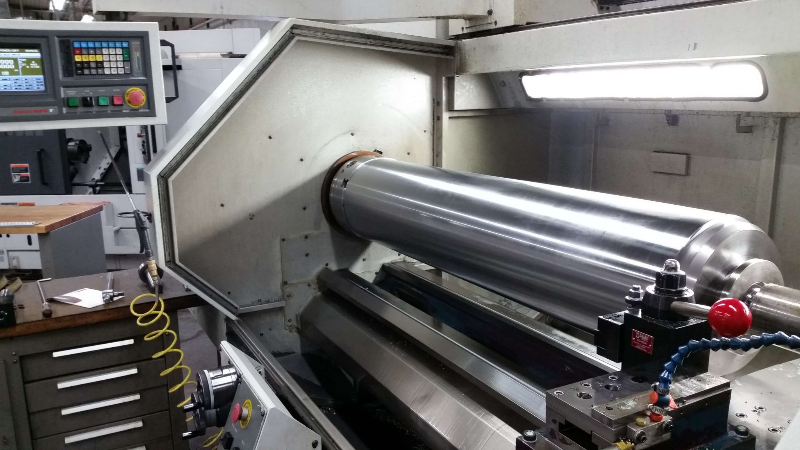

There are a lot of applications for these tips. Because the tips have an AlCrN coating, they are good for sharp corners and specific radial cutting. Some of the applications that these tips have been used for include slotting and roughing on surfaces. They are also used for milling round barrels into octagonal shapes. Some tool makers have also used these tips for profiling. People have used them at speeds of up to 2,500 RPM without any lag or precision loss.

For more information visit Supermill LLC.