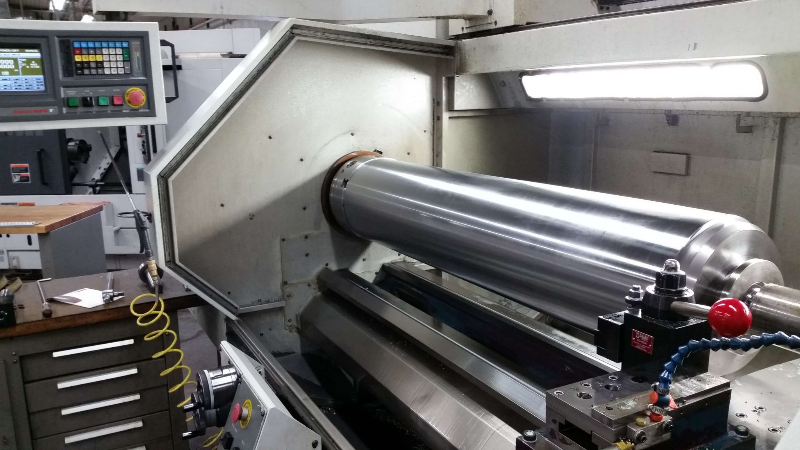

Today’s machine shops may perform a wide range of jobs and you might be working with several types of materials from time to time. Most operations require coolant to keep tools and metal the proper temperature. Without proper cooling, many procedures would not be possible. However, over the course of a day or week, you could go through a great deal of fluids and this can get expensive. This is why a good coolant filter system is essential if you wish to remain competitive. But what kind of equipment is best for your operation? Let’s check out some of the options and see.

Why Should You Recycle Fluids?

To demonstrate the importance of fluid recycling, let’s take the example of a large machine shop and call it “Company A”. This is a big operation and they have 68 people in their employ. They use 47 machines on a regular basis. Many of their orders are for the aerospace and military sectors and they perform high tolerance work, and because they are AS9100 certified, they must maintain strict quality control standards.

During a week’s time, Company A might use steel, aluminum, stainless steel, copper, brass and sometimes plastic. Each month, the shop uses about 250 gallons of coolant. To dispose of this material, it has to be properly packaged and handled according to hazardous waste standards.

Seeing how wasteful this strategy was, the shop installed an effective coolant filter system along with methods for separating oil, water, and metals from the fluids. They also instituted a coolant recovery program. Within a year’s time, Company A was saving around $8,000 a month. In about ten year’s time, this is close to one million dollars.

What Kind of Filtration Program Do You Need?

Are you interested in removing solids, tramp oil, bacteria and separating oil from water? Most shops have these needs. You could invest in several systems to take care of all these needs, or find a company which can handle everything with one system. For example, some systems utilize a centralized coolant filter which provides fresh coolant all the time. It can separate and remove contaminants with special bag filters.

In addition to a coolant filter, some systems also mix coolants for you, so you don’t have to do it manually. This ensures proper concentrations for maximum performance and tool life and because it’s automatic, it eliminates the human error factor.

Can’t Find What You Need?

When you do business with a trusted filtration provider, you can enjoy the benefits of custom made coolant filter equipment. This will give you everything you need in one system.